The Tees Valley - Britain's biomanufacturing engine room

Conditions are conspiring to make biomanufacturing more important to the UK economy than ever before. And Tees Valley is leading the way in this resurgence, as HT World reports.

COVID-19 has triggered a renewed focus on innovating beyond our medical challenges; and a great rethinking of healthcare production lines.

After the lessons learned in the first wave of the pandemic, when nations, including Britain, struggled to meet demand for healthcare equipment, sweeping changes await. Reshoring, unravelling supply chains and a surge in life science and biomedical activity are among the predicted trends ahead.

At the same time, Britain needs inward investment and economic bright spots to power the country back to full strength.

Biomanufacturing, therefore, could be hugely influential over the coming years – creating home-grown opportunities while speeding up the journey of life-saving products from lab to bedside.

An epicentre for this activity could be the Tees Valley, where momentum in the sector has been building for several years; and COVID-19, although presenting logistical challenges, has only accelerated this and sharpened the focus of sector stakeholders in the region.

"We're getting a huge amount of attention"

Tees Valley mayor Ben Houchen proudly points to a growing awareness nationally and in government that his area is becoming a major player in biotech.

In general terms, the Northern Powerhouse’s Health Research Science and Innovation Audit in June 2018 valued the North’s life sciences economy at £13.6bn in 2017, marking a 48% increase from £9.2bn in 2016 and at a growth rate 4.8% higher than the national average.

The North East pharmaceutical manufacturing industry contributed £1.04bn of GVA in 2018. Regional GVA in the sector has been increasing year-on-year and, in the three years leading up to 2018, grew by more than a third in real terms, almost seven times the national increase of just 5%.

Within the North East, the Tees Valley is a particular hot spot and that has not gone unnoticed.

Houchen says: “There’s an awareness in central government and nationally that there is a growing cluster of biotech businesses based in the Tees Valley and that, outside of the golden triangle, Teesside is somewhere that has a sizeable footprint in the sector. From a government and political perspective, we are getting a huge amount of attention.’’

The Tees Valley has been able to build on its traditional strengths in the chemicals and process industries and the spin outs from ICI. It boasts four well-regarded NHS trusts, the Centre for Process Innovation’s (CPI) flagship National Biologics Manufacturing Centre and Teesside University’s National Horizons Centre, all supporting the global healthcare, biologics and pharmaceutical companies operating in the area.

FUJIFILM Diosynth, based in Billingham, is one among the top ten largest employers in the region and has its UK HQ and development site in Billingham.

“They have a good-quality, highly skilled, well-paid workforce and that resonates throughout the region,’’ says Houchen. “People are aware generally of the work that people like FUJIFILM do and there is Hart Biologicals that is doing fantastic work as well.’’

The area also has a strong track record of delivering clinical trials, with around 7,250 patients recruited annually.

The National Institute for Health Research has ranked the South Tees Trust in the top 11% of NHS trusts in the country for the number of participants recruited to trials.

Houchen believes the Tees Valley’s strength in the area has been built on the back of increasing specialisation by Teesside University, which produces more than 3,000 health and life sciences and 3,700 computing, engineering and digital technologies graduates each year. Now the Tees Valley is bidding to build on its strengths and its growing reputation.

“We are lobbying and doing a huge amount of work to try to get the UK’s national vaccine manufacturing centre based in Teesside. We think we have a very compelling case to do that because of the likes of FUJIFILM, which runs similar schemes for some European countries and the US in Texas. We are on the radar nationally for this.’’

FUJIFILM has worked with Novovax in the development of its COVID-19 vaccine to secure a contract which, if successful, means 60 million vaccine doses will be produced at the site in Billingham, creating a significant number of jobs.

The Tees Valley is a major centre for the pharmaceutical industry, and the region is at the forefront of the growing opportunities in the biomanufacturing sector. Find out more here.

Spearheading the

nation's net-zero shift

Tees Valley is an epicentre of clean energy and hi-tech biotechnology activity, as Dr Jen Vanderhoven, director of Teesside University’s National Horizons Centre (NHC) explains below.

Recent decades have seen the Tees Valley’s economic and industrial base shift towards bioprocessing, renewable fuels and bioscience.

While its reliance on steel and petro-chemicals has lessened over time, however, the infrastructure and skills catalysed by these original industries are now helping to drive the region’s ongoing diversification.

For example, in 1965, Tees Valley’s famous ICI plant installed the world’s largest bioreactor in an attempt to cultivate animal feed. This ultimately resulted in a fungal biomass suitable for human consumption – marketed today as one of the world’s leading food brands, Quorn.

In fact, the NHC is now working with Quorn on a Knowledge Transfer Partnership to test different methods of making mycoprotein. Our aim is to develop an even more sustainable production methodology, while enhancing product quality. In wider terms, the NHC’s main purpose is to provide a link between academia and the bioscience industry.

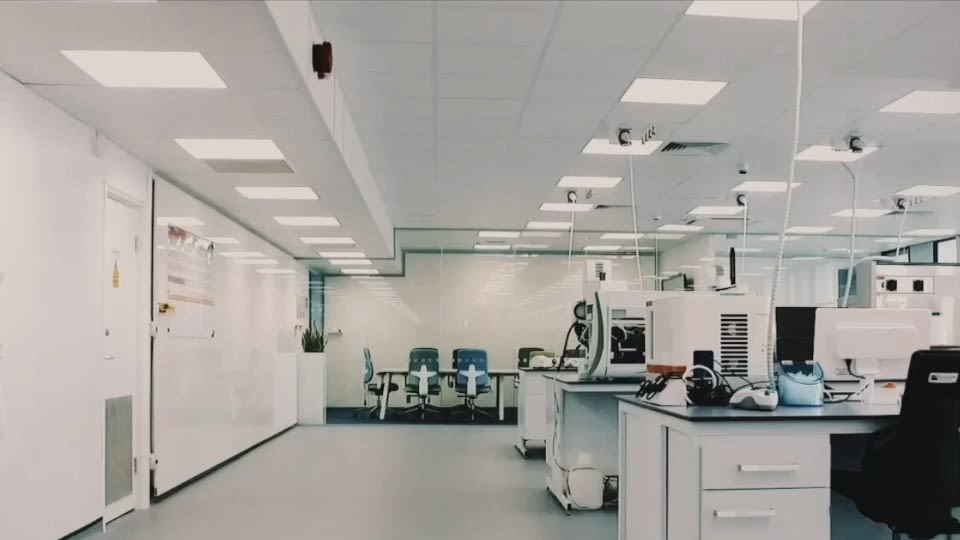

Founded a year ago, the £22.3 million national centre of excellence offers a state-of-the-art teaching, training and research facility for the bioscience industry.

Skills development is a key area of focus. We are creating a pipeline of graduate talent, offering several new undergraduate and postgraduate degrees, helping to train the next generation workforce in areas such as advanced therapies.

Jen Vanderhoven, the NHC

Jen Vanderhoven, the NHC

We’re also designing and delivering programmes, including short CPD courses, to address the technical, leadership and digital skills needs of the bioscience industry.

While developing an internationally competitive applied research and development capability, we are also providing industry with access to specialised world-class facilities.

The NHC’s strengths lie in harnessing new technology and innovation. Our bioprocessing and manufacturing capabilities, for example, are developing new approaches and processes for manufacturing, with a focus on biopharmaceuticals. Our disease-specific research, meanwhile, aims to better understand the biology of diseases and identify novel therapeutic options.

The NHC is also helping the bioscience sector achieve significant productivity gains through the use of unpinning digital technologies in research and manufacturing. Focus areas here include harnessing data analysis, modelling and simulation techniques, and virtual and artificial reality.

For example, at the NHC we have developed a bioreactor virtual reality package for training those making the medicines of the future, where losses and mistakes within biopharmaceutical processes can be significant, and cause delays in getting medicines to those who need them.

The VR package creates an environment where employees can learn and perform tasks without the risk of a mistake in the manufacturing environment. Overall, I believe the Tees Valley is positioning itself as a global leader at the cutting edge of clean energy and biosciences.

With the recent announcement that the Tees Valley is to become home to the National Hydrogen Transport Centre, it’s also spearheading the UK’s shift towards net-zero.

The Tees Valley in numbers

£588m - planned investment in innovation, skills, infrastructure and business by Tees Valley Combined Authority over 10 years

Over 30% growth in the North East's pharmaceutical manufacturing sector between 2015 and 2018, versus 5% nationally

3,000 health and life sciences graduates every year in the

Tees Valley

Working together for the

greater good

An influential force in Tees Valley’s biomanufacturing success is the CPI – which brings together academia, business, government and investors.

The CPI is an independent technology innovation centre and a founding member of the Government’s High Value Manufacturing Catapult.

It was founded in 2004 and applies its experience across a broad range of industries, including pharmaceuticals, medtech, electronics and agritech. It aims to help ensure that every great invention gets the best opportunity to become a successful product with robust, economically viable manufacturing processes.

Working with partners across diverse markets in the UK and around the world, CPI aims to drive innovations while reducing the risk and cost associated with new product development. By providing its partners with access to experts, equipment, networks, funding and more, it hopes to enable and accelerate effective innovation.

CPI has six national centres, five of which are located within the Tees Valley and County Durham region, and a sixth in Scotland. Each of these facilities offers collaborative spaces, advanced equipment and technical expertise to support the development of next-generation products and transformative manufacturing solutions. Graeme Cruickshank, chief technology and innovation officer at CPI, says: “Cross-sector knowledge sharing is enabled across CPI’s teams, with diverse technical expertise applied to a variety of projects. The teams also possess a deep understanding of funding requirements, with experience in securing grant funding, bid support and private investment.”

Two new projects – both part of the national drive to identify and produce effective treatments for COVID-19 – are showcasing CPI’s value as an innovation partner. First, having joined the vaccine manufacturing taskforce, CPI is part of the workstream for Imperial College London’s saRNA vaccine candidate.

This workstream includes evaluating the scale-up and development of the saRNA vaccine platform technology using its skills, capabilities and expertise. In addition, CPI is participating in a UK consortium developing antibodies for treating COVID-19. The taskforce has successfully identified a set of antibodies with great potential and CPI will play a key role in their manufacture.

Both these activities are being conducted at CPI’s National Biologics Manufacturing Centre at Central Park in Darlington, which is co-located with the Teesside University-led National Horizons Centre.

Cruickshank adds: “This cluster of innovation in the North East has begun to transform the region into a hub of biotechnology. Bolstered by its strong research institutions and talented, forward-looking people, the region stands out as a leader in life sciences. This will continue to enable the creation of high-value jobs, while benefitting the economy and the public through next-generation innovations.

“With manufacturing deeply rooted in the North East, CPI’s leadership in innovation is supporting the region to showcase this capability to the world. Ultimately, the growth and development of the industry will help reinforce the hub of innovation that has already begun in the area. This will cement the position of the North East as leaders in this new bioeconomy sector locally, nationally and internationally.’’

Graeme Cruickshank

Graeme Cruickshank

Space to realise Tees Valley's biomanufacturing potential

Tees Valley’s Wilton Centre is part of a national network of science parks, although it is one of the biggest, with 60 occupiers employing around 750 people.

It has several offices and laboratories of different sizes, which can accommodate start-ups – and it has several companies which began as spin offs from universities – more established businesses and global companies.

Claire Morton (pictured), the accommodation manager, says: “Some of our occupiers have arrived here with very few staff but have grown and grown. It’s great that we are able to provide that flexibility and it means that our occupiers can concentrate on the job in hand rather than being distracted by the upheaval of a move. We welcome businesses from a wide range of sectors, but science is at the heart of what many of them do. The Wilton Centre used to be the headquarters of ICI, so research and science is very much part of our DNA.’’

The Government recently announced that two of the centre’s tenants had been awarded more than £7m as they prepare to build plastic recycling plants on Teesside. Poseidon Plastics’ plant will recycle the equivalent of a billion plastic bottles a year. ReNew ELP’s plant will handle around 80,000 tonnes a year of waste plastic hitherto considered unrecyclable.

Two other tenants, Absolute Antibody and Micropore Technologies, are doing ground-breaking work in biotech.

The former, which moved to the Wilton Centre six years ago, is being presented with a Queen’s Award for Enterprise in International Trade. It works with the world’s leading pharmaceutical companies which are trying to develop vaccines or treatments. It specialises in antibody sequencing, engineering and recombinant production. Its work is particularly valuable to pharmaceutical businesses which are trying to develop treatments. Demand for its expertise has been so strong that the company has almost tripled in size since March 2020.

Micropore Technologies is also generating significant interest across the world as it has developed a technology which would provide the companies which are developing COVID vaccines with both the precision and large-scale production capability they are going to need, through a process called membrane emulsification. Morton says: “Micropore’s technology provides a new, accurate and scalable method of creating emulsions – the process of blending insoluble liquids – which is a vital stage in the development of liposomes for a synthetic vaccine.’’

Building strength in numbers

Bionow is a not-for-profit membership organisation which supports the biomedical, pharma and life sciences sectors across the North of England.

It does this through conferences and events across the North, being an advocate for the region, and providing procurement benefits and other specialist products and services for members to strengthen the competitiveness of the North’s innovative life science sector.

Its more than 270 members range from universities to multinational pharma companies, to biotech, medtech and the professional and technical service support companies that support the sector.

Chief executive Geoff Davison says: “The Tees Valley has a strong and growing biotech sector, with several Bionow members based in the region, and was a natural choice for Bionow to hold the annual 2019 Pharma Manufacturing Conference in Darlington. The conference enabled us to bring pharma companies from across the North and beyond to network and share good practice.

“When drawing up the conference agenda we formed a conference steering group involving local Bionow members such as Centre for Process Innovation, FUJIFILM Diosynth Biotechnologies, Teesside University and Tees Valley Combined Authority. Thus, we could address some of the challenges and opportunities that face the Tees Valley within the conference programme.’’

He points out that the Tees Valley can draw upon the human resource legacy from the ICI years and a local workforce equipped with skills spanning pharmaceuticals, chemicals and engineering.

“Tees Valley’s heritage means that it has strong infrastructure on a facilities level, and a technical and a skills level, which is a combination and advantage not found in every other area,’’ adds Davison.

“Additionally, with Darlington being on the East Coast Main Line and the recent developments at Teesside International Airport, the area enjoys good connectivity which makes it very attractive and accessible to investment and collaborations with people from across the UK and beyond.

“The connectivity of the region is a very important point, as the Life Sciences sector is global in nature, and collaboration with partners across the Tees Valley, the North of England and beyond is crucial to the success of many projects, and that is where organisations such as Bionow fill a vital role, by bringing people together and connecting companies and academics.’’

He emphasises the importance of collaboration and also points to Tees Valley assets, such as the National Horizons Centre in Darlington, CPI’s National Biologics Centre, NetPark and universities and companies around the wider region.

He says: “Looking forward, the Tees Valley is in a strong place. After the pandemic there will be questions asked about supply chains, companies are going to want them to be closer to home and more accessible, this will suit the Tees Valley in a number of ways, as an important place to source key resources and also to look for research project partners.

“The digital revolution also assists the Tees Valley, as companies are going to look to have smaller connected production units. This can lead to smaller, more nimble operations using highly skilled personnel making small batch medicine, as opposed to the traditional large-scale processing. Though that will still have a role, which is where having a great human resource and training facility, such as the National Horizons Centre, is a great asset.

"We can see evidence for this with FUJIFILM's investment in a BioCampus and cell and gene therapy development and manufacturing both at Billingham. Developments like that put the Tees Valley in a strong position to embrace the changes that are coming in this rapidly changing sector.’’

Register here for future insights

Useful resources

The Tees Valley is a major centre for the pharmaceutical industry, and the region is at the forefront of the growing opportunities in the biomanufacturing sector. Find out more here.

Watch out for more on Tees Valley's biomanufacturing development on Health Tech World in the coming months. In the meantime, find out more below:

Invest Tees Valley

Bionow

CPI

Wilton Centre

National Horizons Centre